17th December, 2025

Building a house whether it’s a compact G+1 family home or a G+2 structure – is one of the biggest investments most people make. And the one material that silently holds your home together is the TMT bar. Choosing the best TMT bars for house construction is not just about picking a popular brand – it is about selecting the right grade, ductility, strength, bonding capability with concrete and diameter for every part of your RCC (Reinforced Cement Concrete) structure.

This guide explains everything a homeowner, supervisor, or engineer should check before buying TMT Saria for residential construction. Updated for 2025–2026 based on current BIS standards, construction practices, and seismic safety considerations in India.

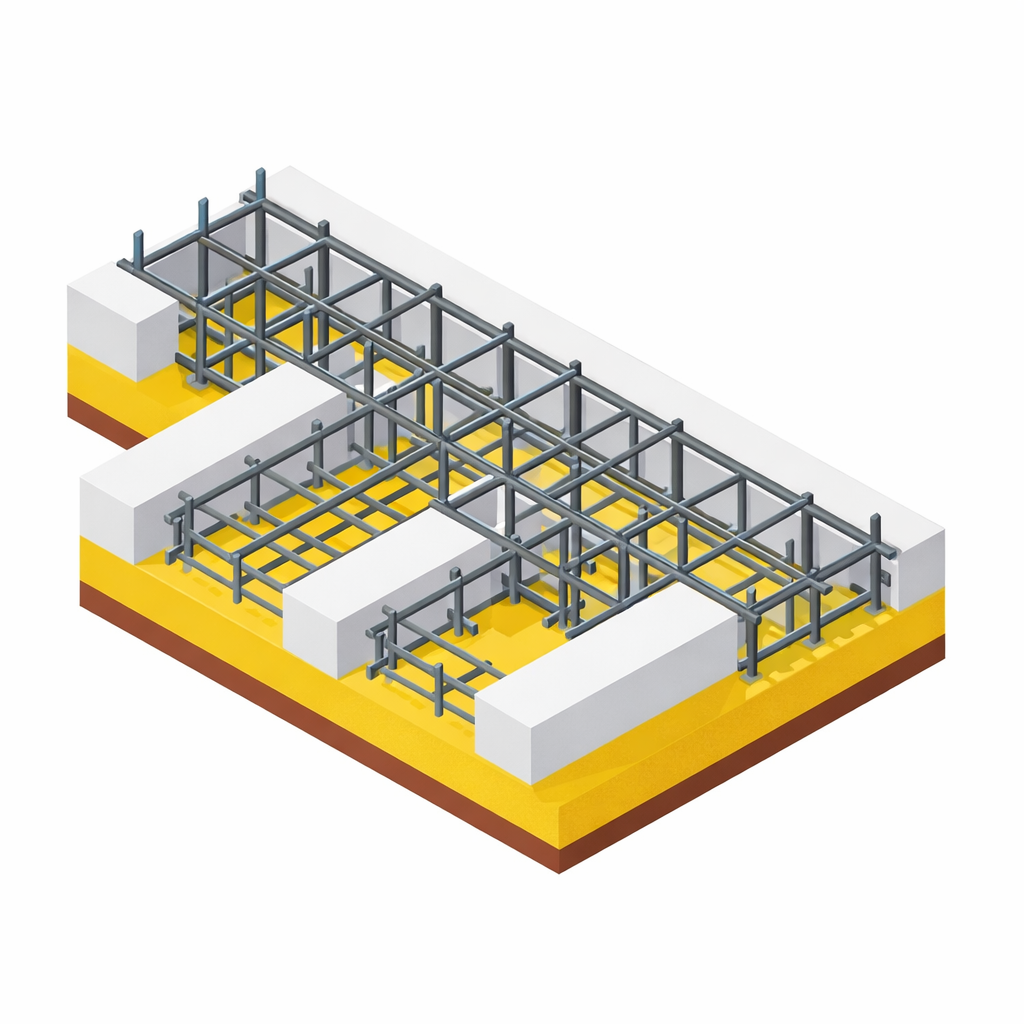

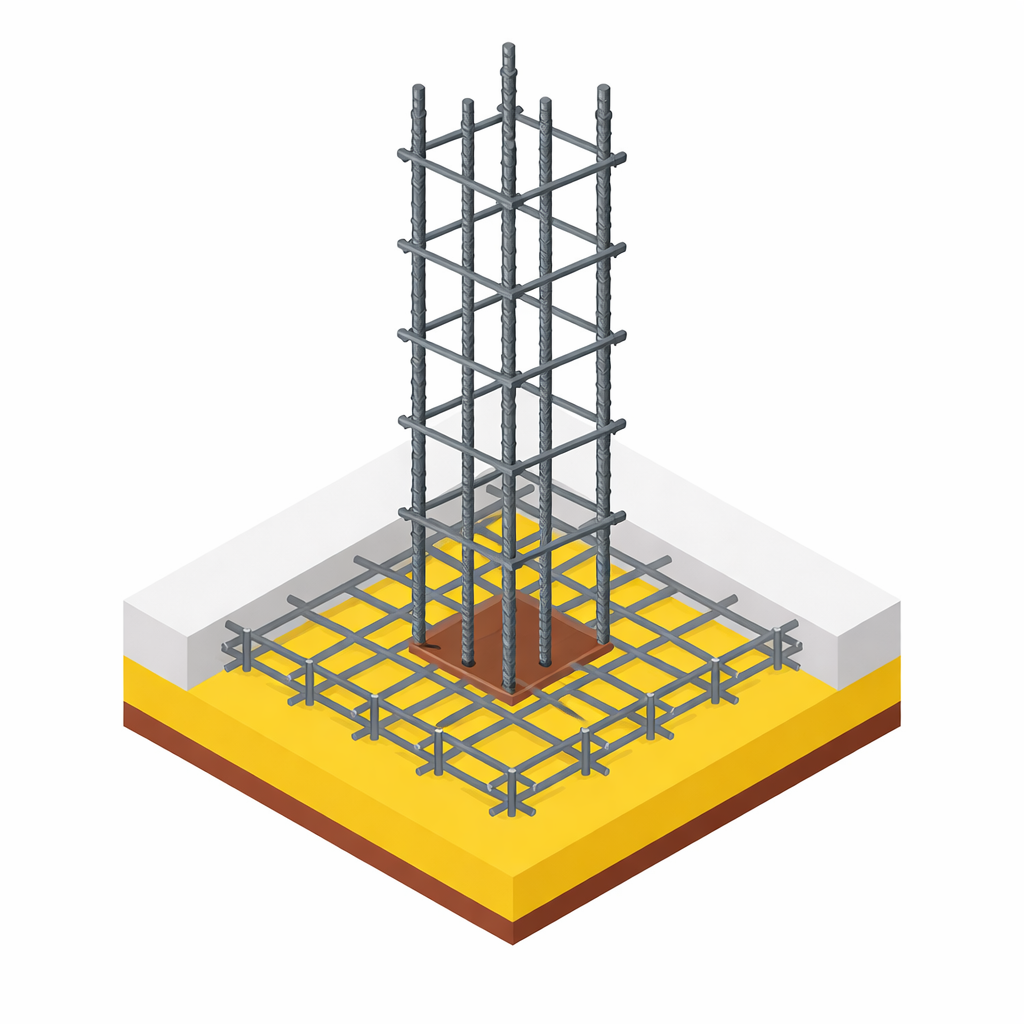

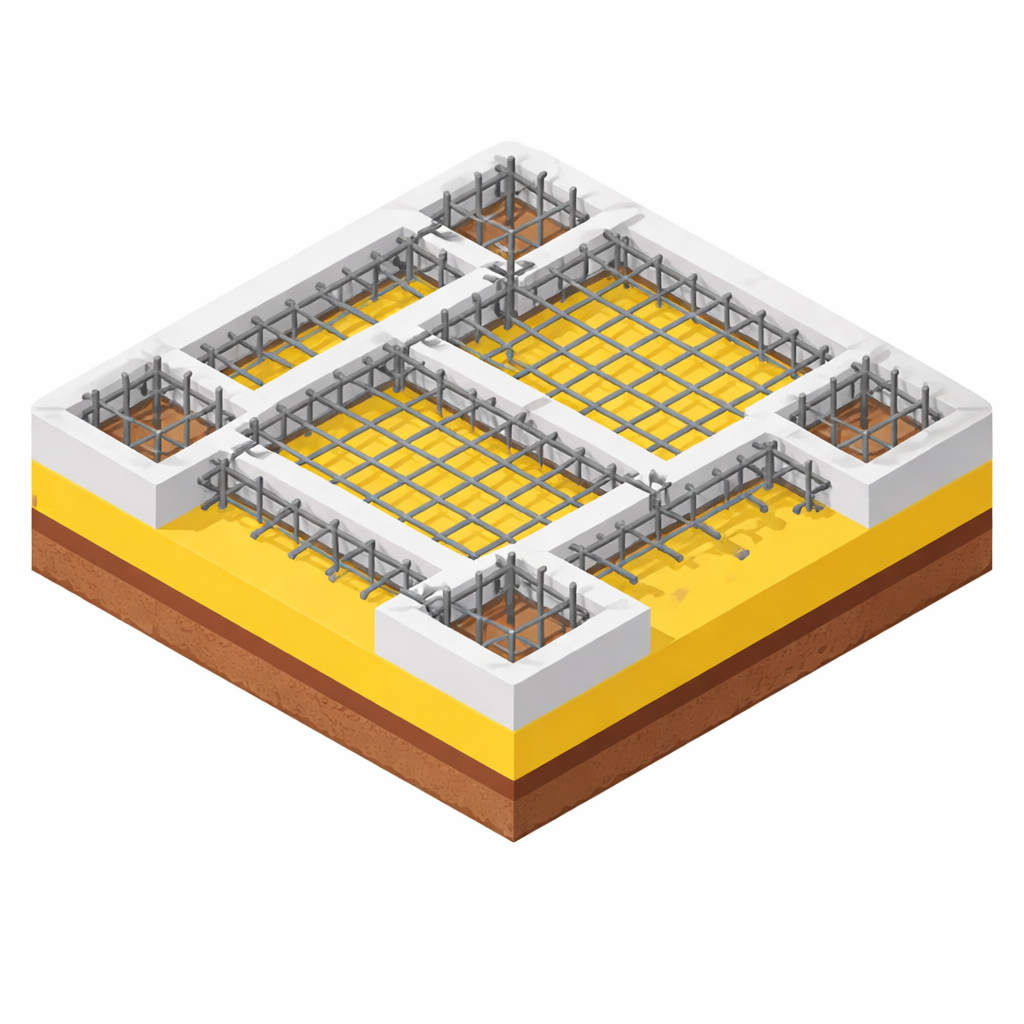

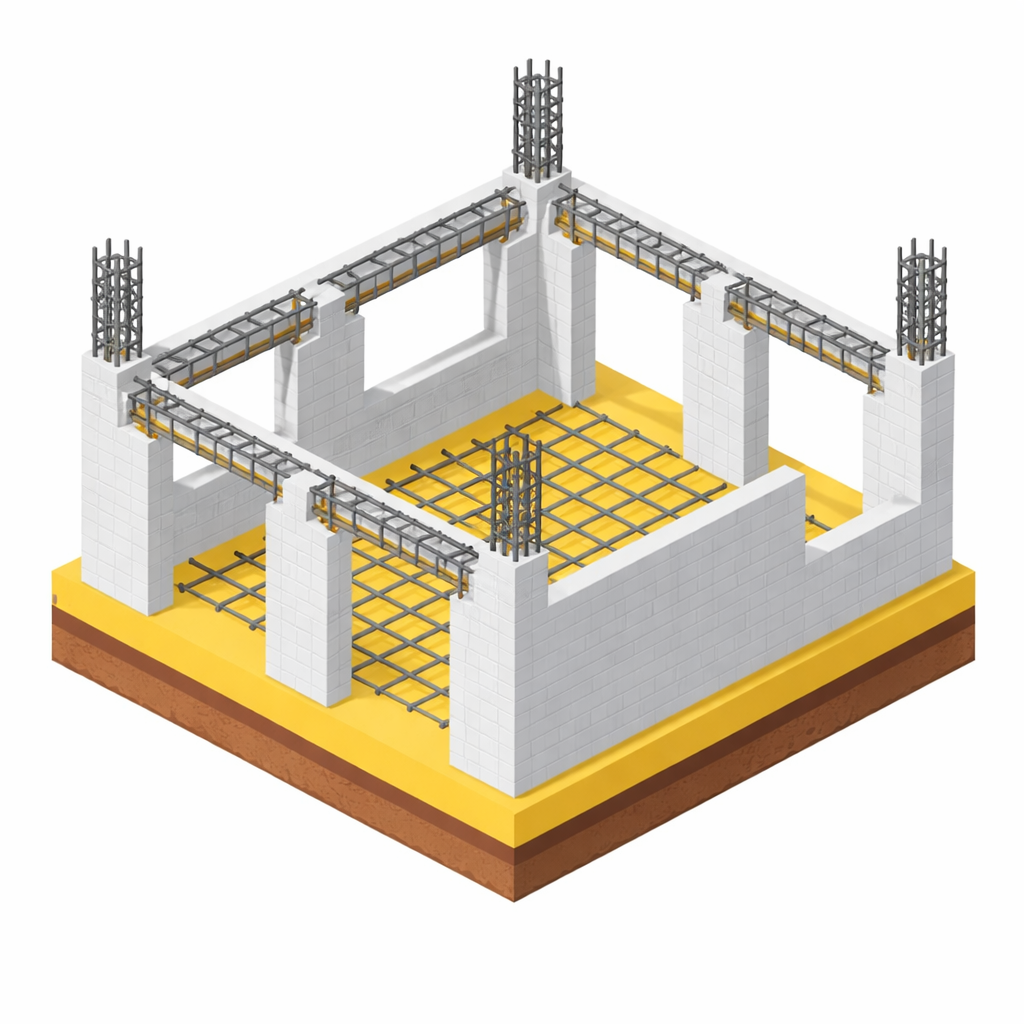

Every major load-bearing section of your home relies on TMT bars:

Beams

Columns

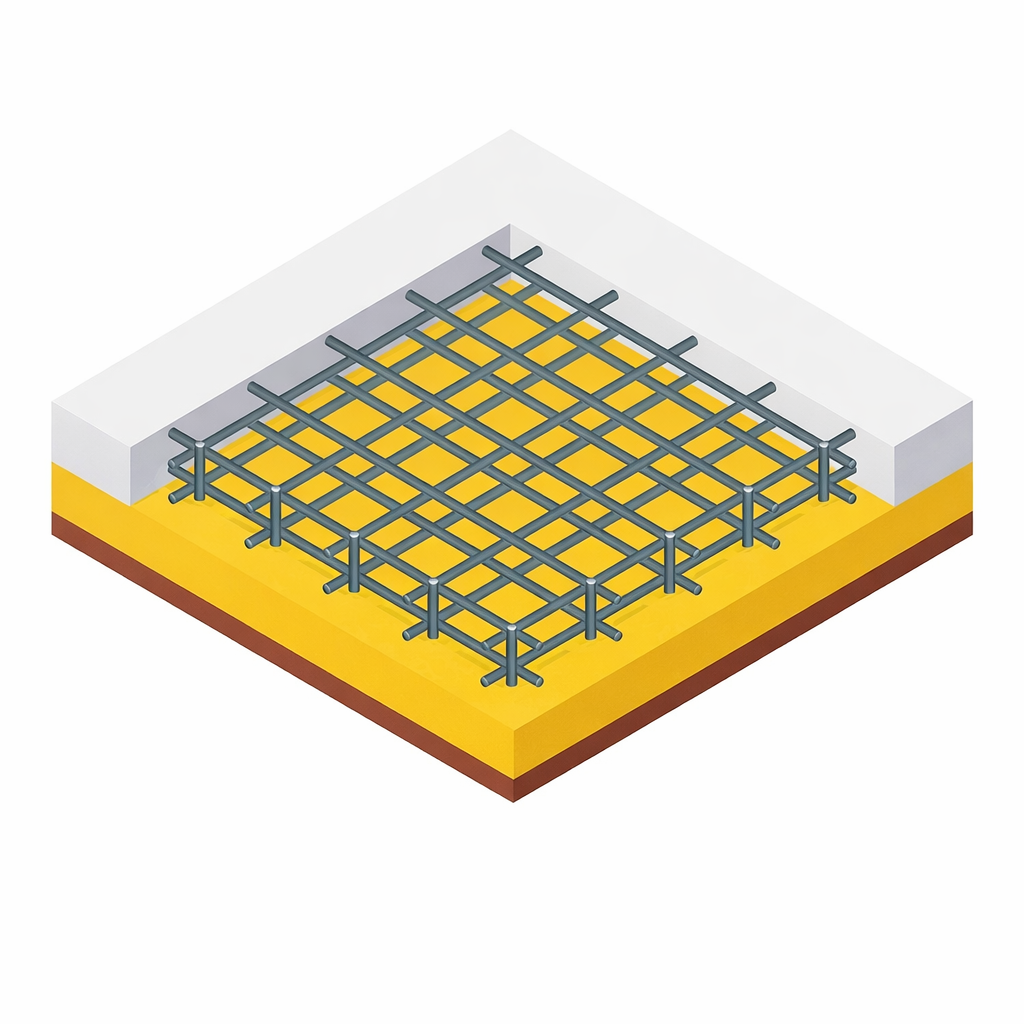

Foundation

Lintel Roof Supports

Slab

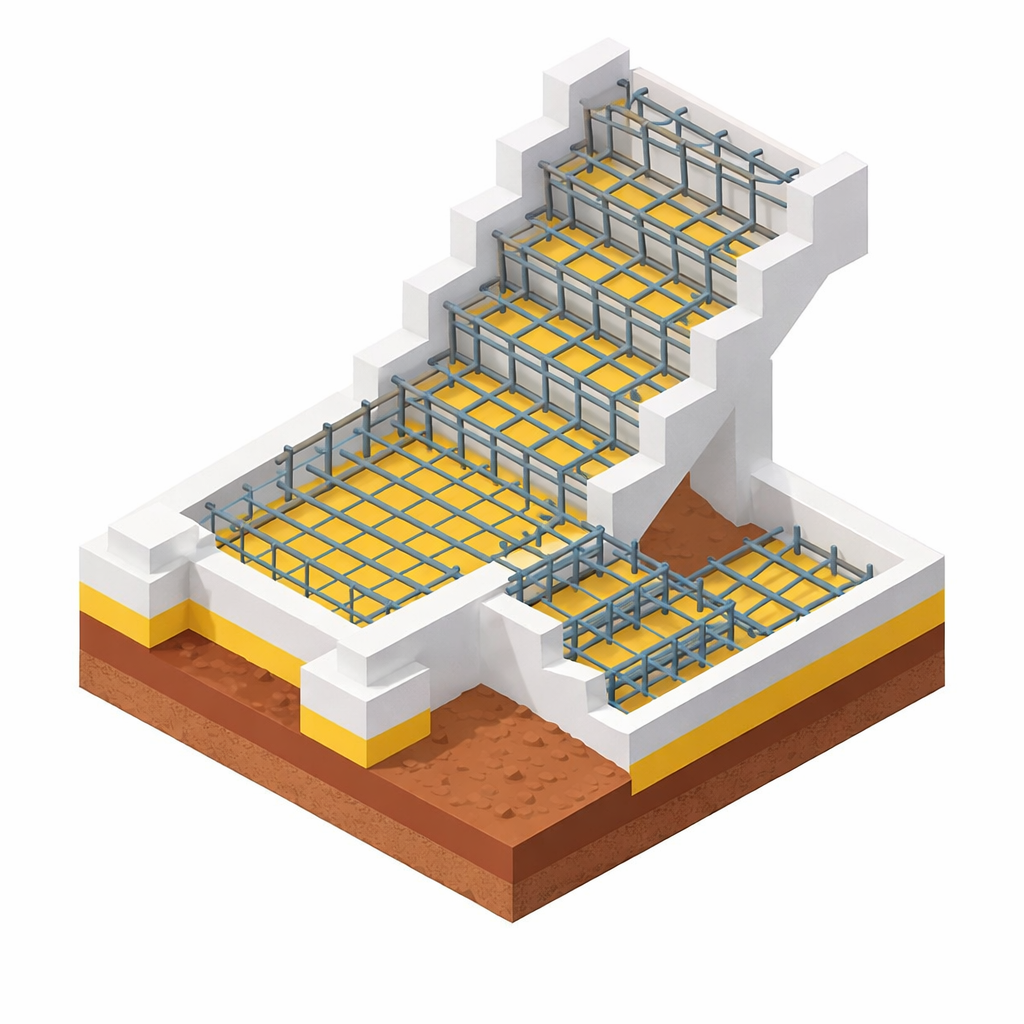

Staircase

TMT bars handle the tension, bending forces, wind load, and seismic stress that concrete alone cannot withstand.

If low-quality steel is used, even premium cement cannot prevent structural failure. Choosing the wrong grade or diameter can reduce your home’s lifespan by 10–20 years, especially in seismic zones and areas with weak soil.

For most residential RCC houses (G+0 to G+2 and above), Fe 500D is the safest and most recommended grade. Current recommendation for residential projects in 2025–2026.

Industry Note: Many homeowners today prefer TMT bars that combine high ductility with consistent rib geometry for better bonding. Brands like Kay2 XENOX, known for their controlled manufacturing and optimized rib patterns, are often considered where long-term structural reliability is a priority.

Fe 550D is stronger but slightly less ductile. Choose it only when:

It should always be used under civil engineer supervision.

| Feature | Fe 500D | Fe 550D |

|---|---|---|

| Ductility |

⭐⭐⭐⭐⭐ (Best for homes) |

⭐⭐⭐⭐ |

| Tensile Strength | High | Higher |

| Earthquake Resistance | Excellent | Very Good |

| Usage | Recommended for G+0 to G+2 constructions as well as high-rise structures. | Applicable for G+2 and higher structures, within prescribed design limits. |

| Ease of Workability | Easy to bend & cut | Slightly rigid |

| Recommended for homeowners? | ✔ Yes | Conditional |

Verdict -

For 90% of Indian houses, Fe 500D is the ideal and safest choice.

For 3+ floors, Fe 550D may be used — but only as per RCC design.

Civil engineers typically suggest the following bar sizes for a balanced and economical RCC structure:

Using the correct bar diameter prevents over- and under-reinforcement, optimizes material usage, reduces cost, and enhances structural performance.

Compliance with CPWD, IRC & NDMA Guidelines (Earthquake Safety)

In seismic-prone regions, the performance of TMT bars is not judged by strength alone, but by how safely they behave during ground movement. That is why Indian construction guidelines emphasize ductility, controlled elongation, and bonding strength in reinforcement steel.

When choosing the best iron bars for construction, focus on these technical parameters — not branding alone.

Dimensions of ribs or optimized rib patterns (e.g., hexagonal) improve grip with concrete. Better bonding = safer beams & slabs.

Higher ductility ensures steel can bend without cracking during:

Important for regions with:

Steel must retain strength under high temperatures.

Always buy steel that meets IS 1786 standards.

Premium TMT bars maintain highly consistent weight across batches. Weight variations above & under the limit indicates poor quality control.

A practical selection breakdown for different home sizes:

→ Should only be used exactly as per structural drawings.

Avoid these common errors to prevent long-term structural issues:

Even the best-quality steel loses efficiency if handled incorrectly.

Fe 500D is best for most homes due to its ideal balance of strength and flexibility.

Fe 500D → Best for G+0 to G+2

Fe 550D → Only for special designs or 3+ floors

Fe 550D is stronger, but ductility matters more for residential structures.

Yes-but only if the brand ensures:

Recommended for:

Selecting the best TMT bar for house construction is ultimately about choosing steel that matches your home’s height, load, and soil conditions. For 90% of Indian homes, Fe500D TMT bars with strong bonding ribs and high ductility offer the safest and most durable performance.

A well-chosen TMT bar ensures that your house remains strong for 50–70 years, making it one of the most crucial decisions in your construction journey. A practical selection guide aligned with 2025–2026 residential construction standards in India.

Written & Reviewed By:

Team Kay2 XENOX – a trusted name in the steel and construction industry for several decades, backed by years of hands-on experience in TMT bars, steel products, building materials, and construction technology.

All information has been reviewed using brand specifications, engineering standards, and authenticated industry insights to ensure technical accuracy and reliability.